After pretty bad oil usage and a compression check that showed 95psi for #4, it was time to rebuild the engine.

I wanted it done right so I towed it to Turbo Time in Cary, NC for the job. All rebuild pics courtesey of Turbo Time.

After pretty bad oil usage and a compression check that showed 95psi for #4, it was time to rebuild the engine.

I wanted it done right so I towed it to Turbo Time in Cary, NC for the job. All rebuild pics courtesey of Turbo Time.

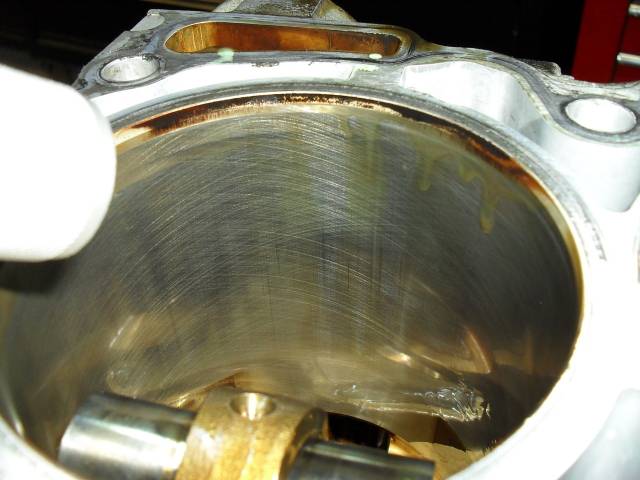

Yep, there's our problem.

Looks like it screwed up the block too.

So, we bought some goodies from Wiseco, Eagle, and ARP, along with a KillerB oil pickup.

And I bought a used block from TT to save machining costs on my original block.

The bore was checked:

Pistons and rods were balanced:

Calico bearings were used as assembly began:

Pistons going in:

ARP studs secure the heads:

All of which lead to the final dyno tuning: